VIGIFLAP

APPLICATIONS

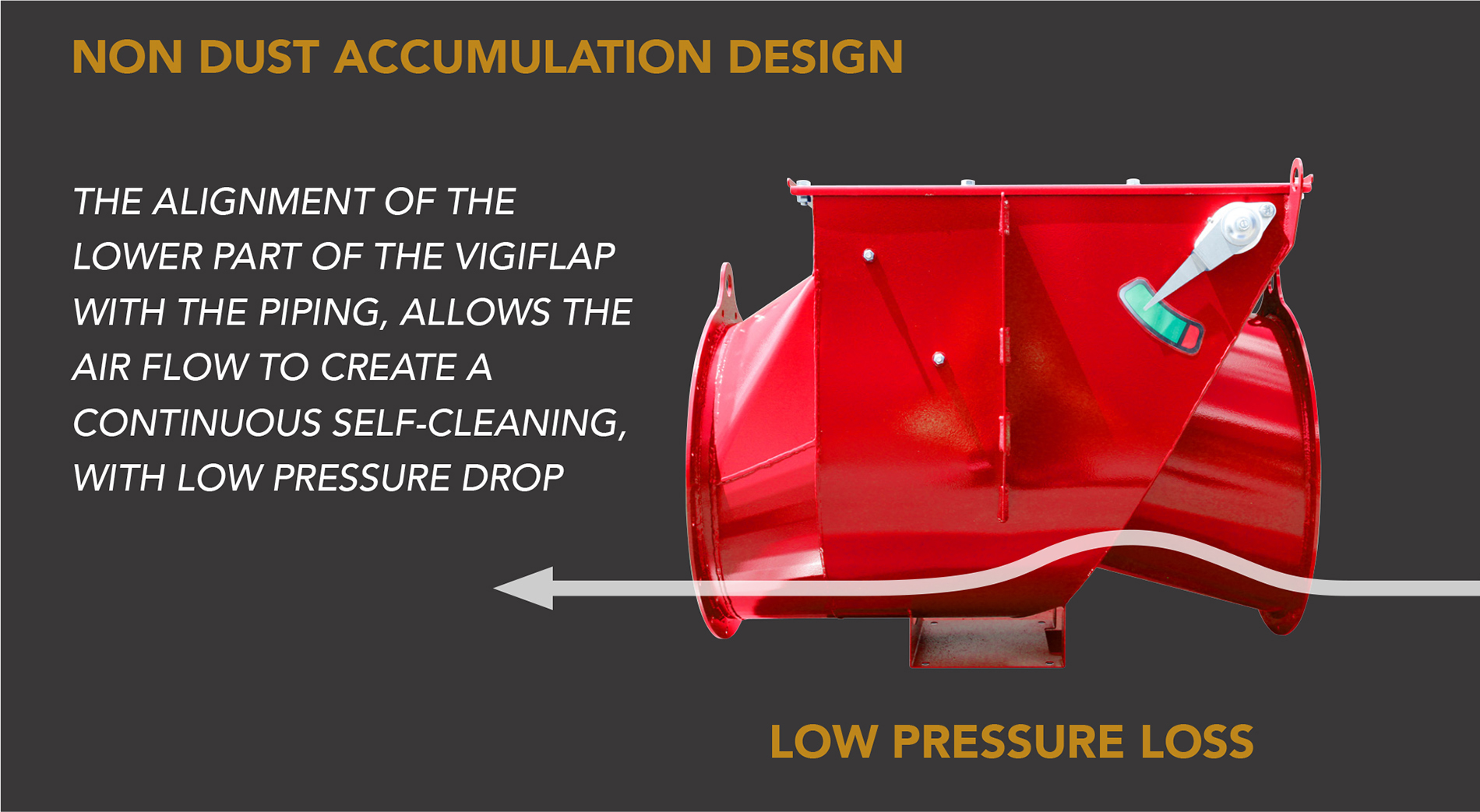

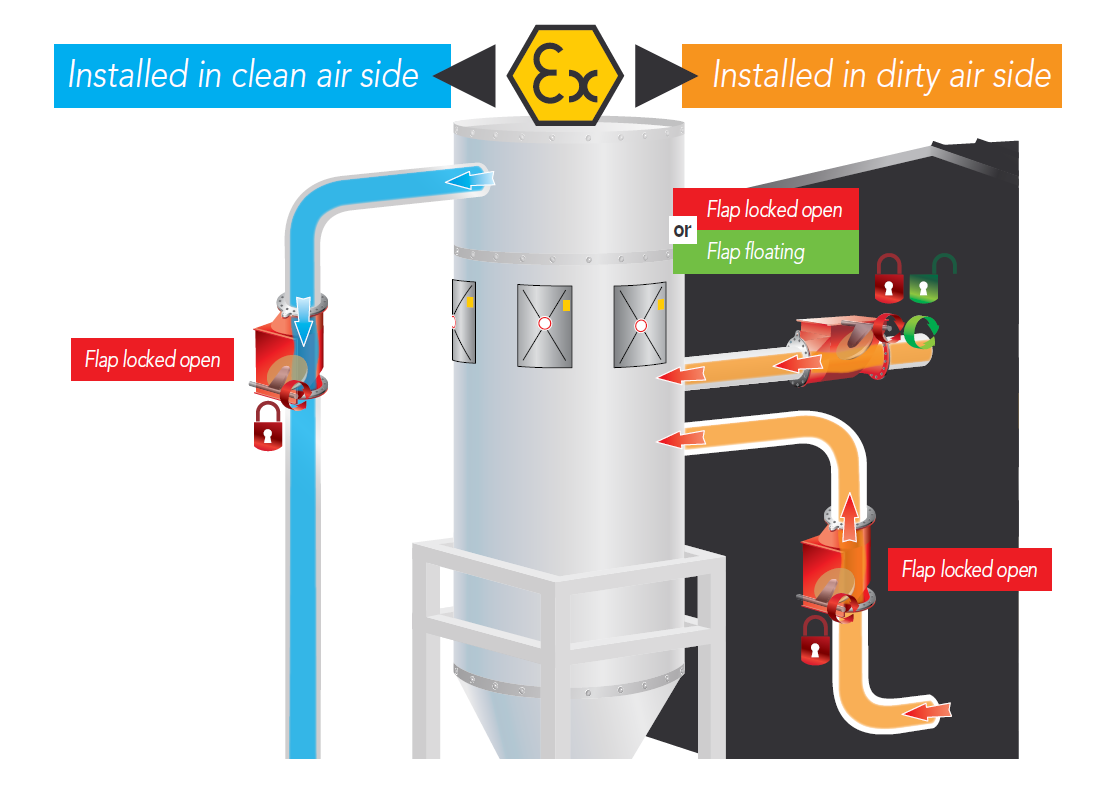

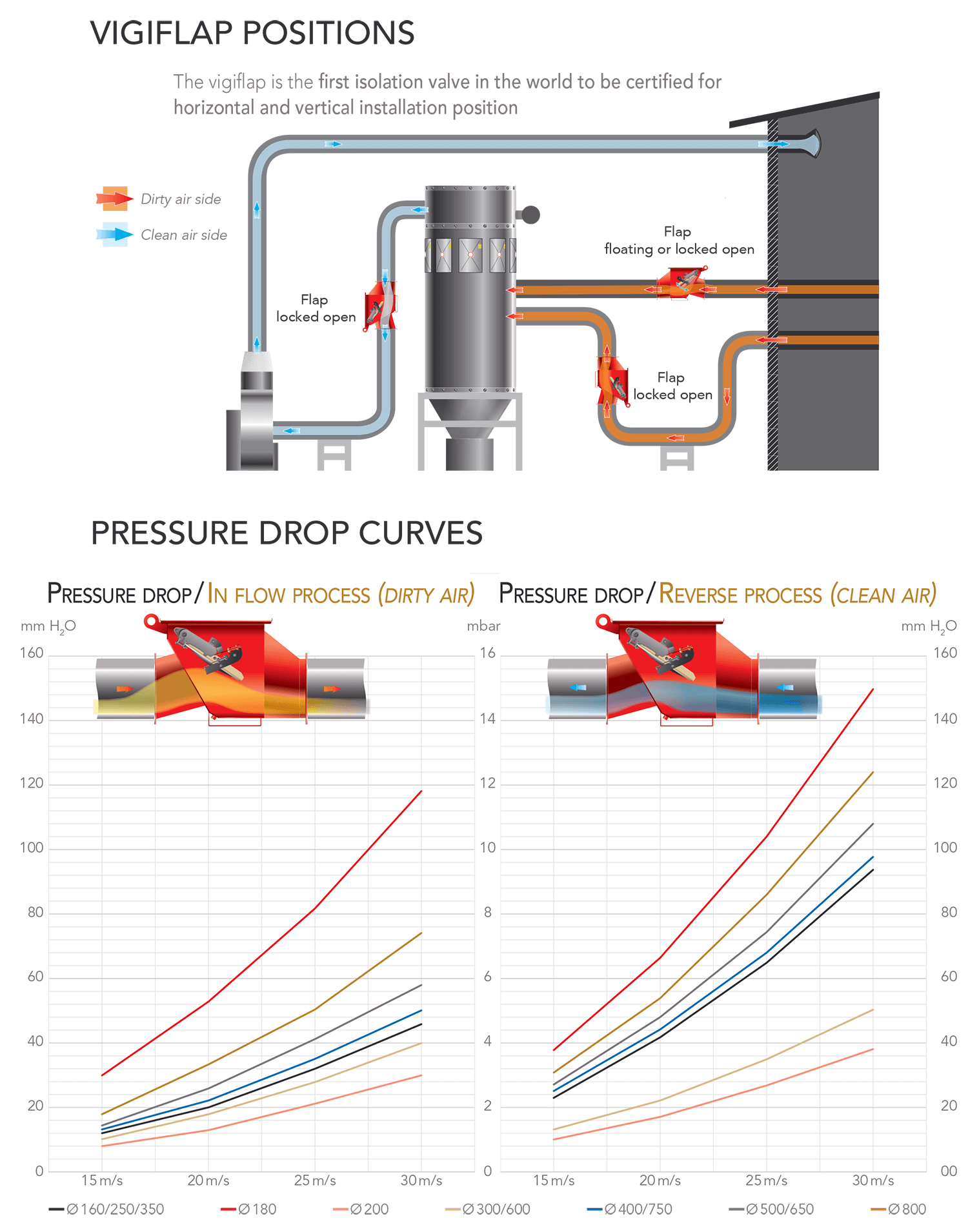

The VigiFLAP is a non-return valve designed to prevent overpressure or flame caused by a downstream explosion (dust collectors, filters, cyclones…) to propagate in the piping system.

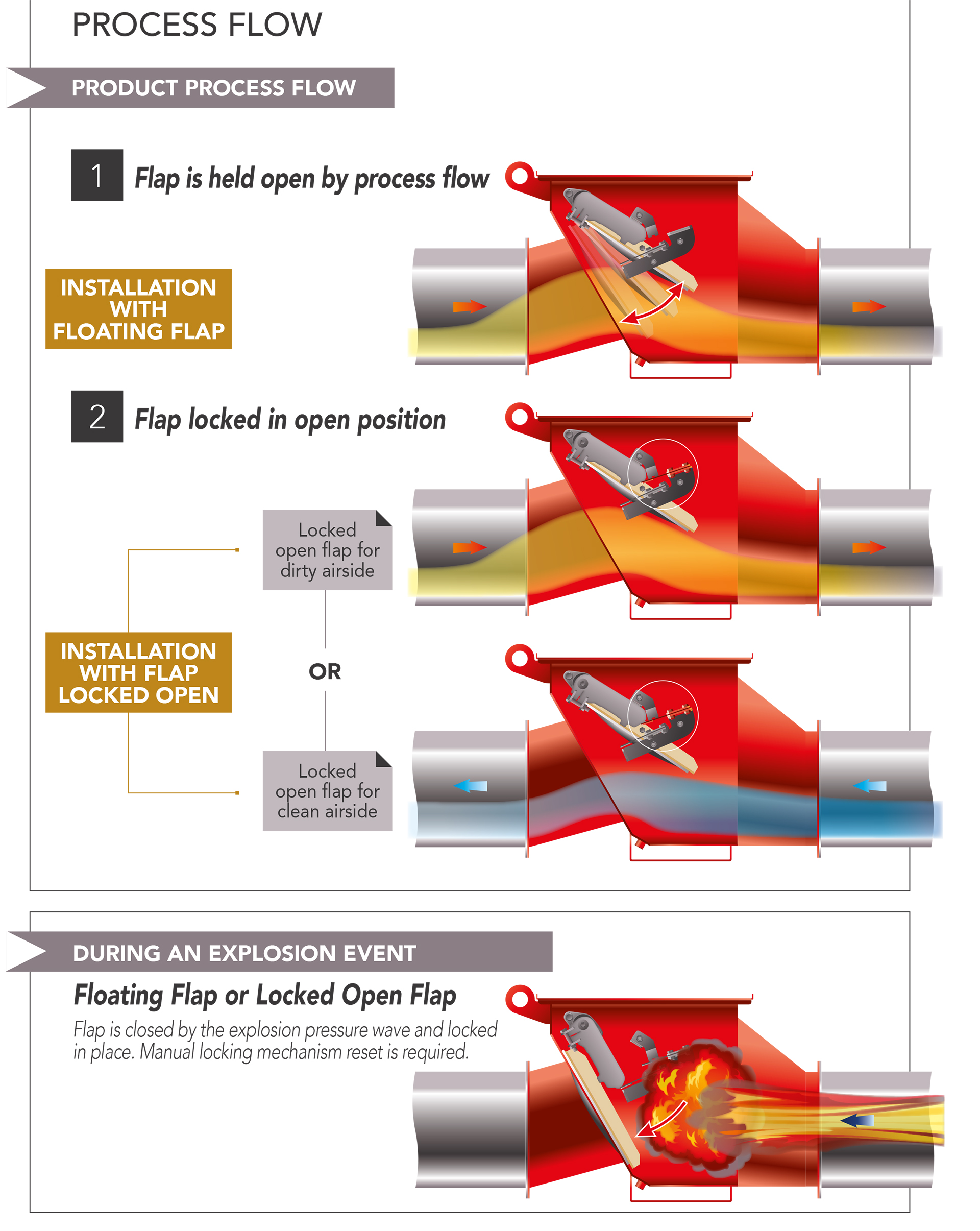

The valve is held open by a lever arm. It can be used both at the entrance and at the exit of the filter. This allows to isolate the filter from an explosion or an overpressure.

In case of explosion, the valve closes and remains locked preventing the progress of the flame. The unlocking of the flap is done manually.

Explosion Isolation valve

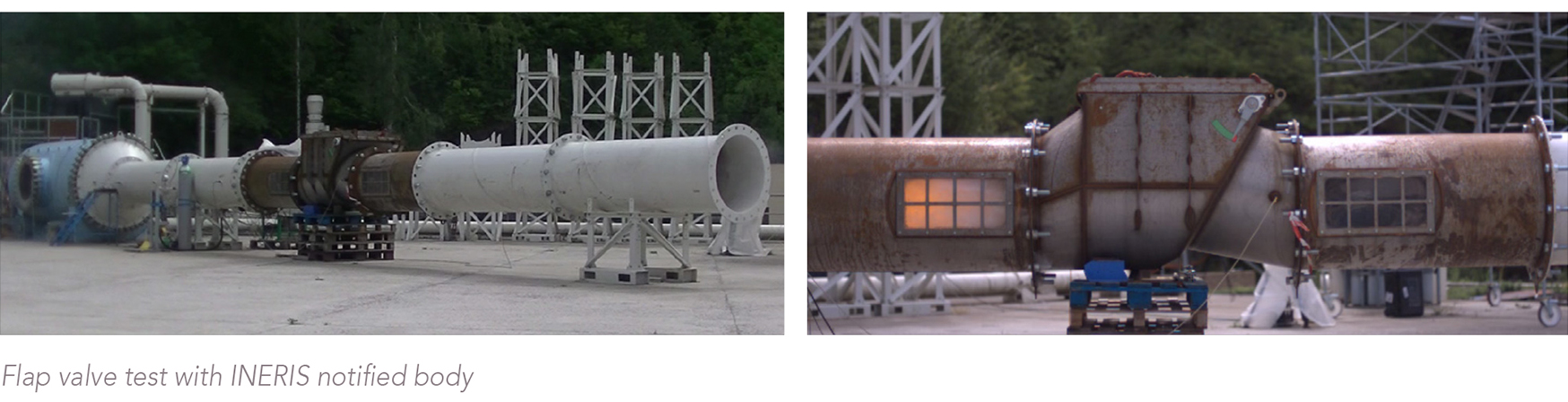

HIGH CERTIFICATION TEST

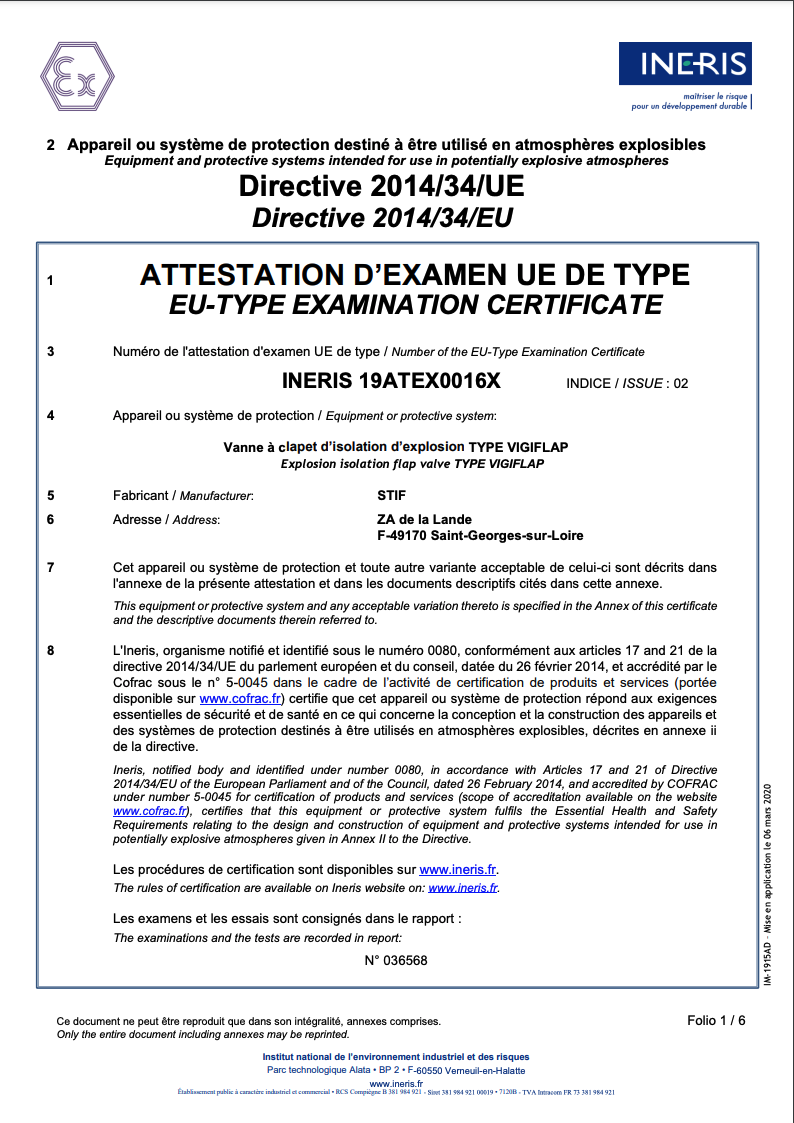

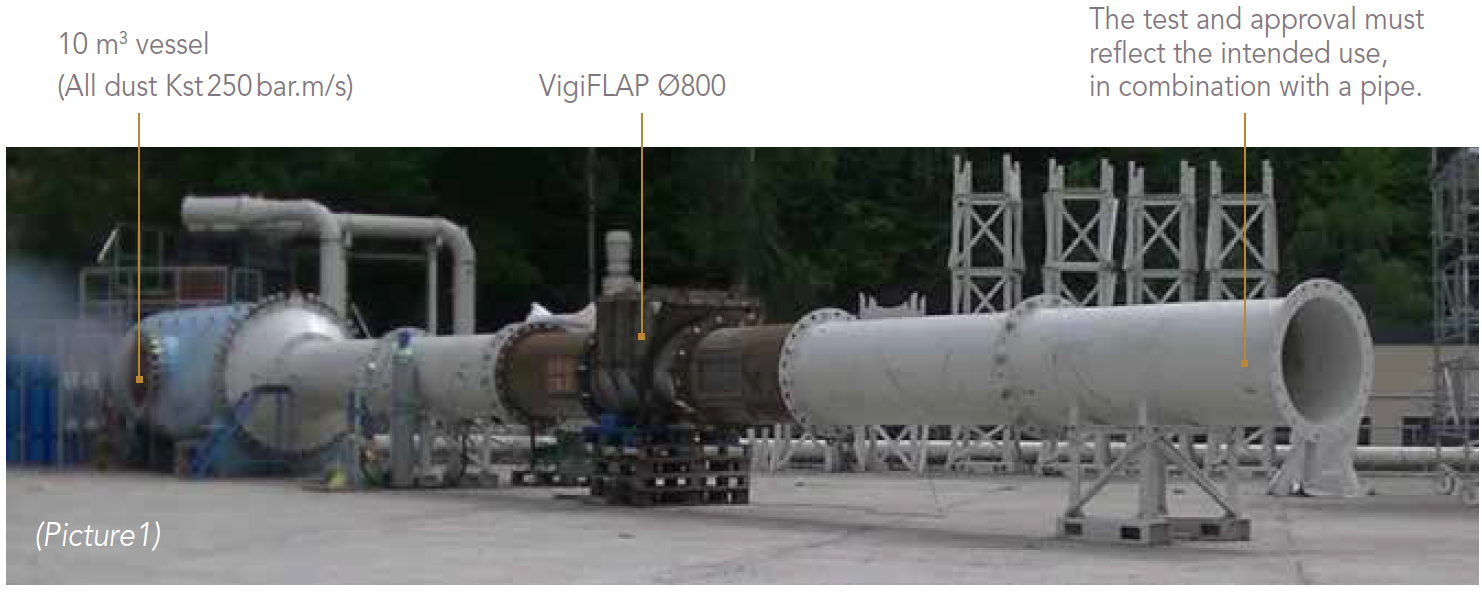

To get our Atex certificate (N° INERIS 19ATEX0016X) according to the standard EN16447: 2014, we carried out our explosion tests in the most extreme conditions and as close as possible to the reality of the use of the product, with for example:

- Protected Zone Pipeline :

All test carried out with a pipeline after the flap (picture1). - Flap locked open:

Automatic release of the valve by the pressure of the explosion - Floating flap:

During the test the flap valve is held fully open until the appropriate

time of release. - Vent panel on test vessel:

No open ports were used during test but vent panels were always used.

SOON:

In few months our VIGIFLAP certificate will be improved with the following additionnal features Atex certified :

- Size until diameter 1370mm

- ST3

| DN (mm) | DN (inch) | Minimum Vessel Volume | LMin* Min Mounting Distance | LMin** Min Mounting Distance | L Max Max Mounting Distance | Download PDF (mm) | Download PDF (inch) | |

|---|---|---|---|---|---|---|---|---|

| DN (mm) | DN (inch) | Volume minimal | LMin * Distance de montage minimale | L Min+2m** Distance de montage minimale | L Max Distance de montage maximale | Télécharger PDF (mm) | Télécharger PDF (inch) | |

| DN (mm) | DN (Pulgadas) | Volumen minimo del recinto | LMin* Distancia mínima de montaje | L Min+2m** Distancia mínima de montaje | L Max Distancia máxima de montaje | Descargar PDF (mm) | Descargar PDF (Pulgadas) | |

| DN (mm) | DN (inch) | Min. Volumen | L Min * Min. Montageabstand | L Min+2m ** Min. Montageabstand | L Max Max. Montageabstand | HERUNTERLADEN PDF (mm) | HERUNTERLADEN PDF (inch) | |

| Диаметр (mm) | Диаметр (дюйм) | Минимальный объем сосуда | L min* Минимальное расстояние монтажа | L min** Минимальное расстояние монтажа | L max Максимальное расстояние монтажа | ЗАГРУЗКА PDF (mm) | ЗАГРУЗКА PDF (дюйм) | |

| VIGIFLAP Ø | 160 | 6“ | 0,70m3 | 4,0m | 6,0m | 17m | PDF | |

| VIGIFLAP Ø | 160 | 6“ | 1,35m3 | 3,0m | 5,0m | 17m | PDF | |

| VIGIFLAP Ø | 180 | 7“ | 0,70m3 | 4,0m | 6,0m | 17m | PDF | |

| VIGIFLAP Ø | 180 | 7“ | 1,35m3 | 3,0m | 5,0m | 17m | PDF | |

| VIGIFLAP Ø | 200 | 8“ | 1,35m3 | 4,6m | 6,6m | 17m | ||

| VIGIFLAP Ø | 250 | 10“ | 1,35m3 | 4,0m | 6,0m | 17m | ||

| VIGIFLAP Ø | 300 | 12“ | 2,90m3 | 4,6m | 6,6m | 17m | ||

| VIGIFLAP Ø | 350 | 14“ | 2,90m3 | 4,2m | 6,2m | 17m | ||

| VIGIFLAP Ø | 400 | 16“ | 4,50m3 | 5,2m | 7,2m | 17m | ||

| VIGIFLAP Ø | 450 | 18“ | 4,50m3 | 4,7m | 6,7m | 17m | ||

| VIGIFLAP Ø | 500 | 20“ | 6,05m3 | 5,8m | 7,8m | 17m | ||

| VIGIFLAP Ø | 550 | 22“ | 6,05m3 | 5,5m | 7,5m | 17m | PDF |

|

| VIGIFLAP Ø | 600 | 24“ | 7,65m3 | 7,2m | 9,2m | 17m | ||

| VIGIFLAP Ø | 650 | 26“ | 7,65m3 | 6,7m | 8,7m | 17m | ||

| VIGIFLAP Ø | 700 | 28“ | 7,65m3 | 6,4m | 8,4m | 17m | PDF | |

| VIGIFLAP Ø | 750 | 30“ | 10,00m3 | 7,3m | 9,3m | 17m | PDF | |

| VIGIFLAP Ø | 800 | 32“ | 10,00m3 | 6,9m | 8,9m | 17m |

* Floating in horizontal position:

Flap valve activated by the working air flow

** Vertical position

With elbows

Flap valve kept open by its spring blade system

| Kst max | ≤250 bar.m/s |

| Kst min | No limit |

| Pmax | 10 bar 145 psi |

| MIE | ≥10mJ |

| MIT | ≥400ºC ≥752ºF |

| MESG | 1,7mm 0.067inch |

| Pred max * | ≤ 0.5 bar |

| VIGIFLAP Resistance | 2.0 bar |

| Marque ATEX |  II D II D |

| Atex inside | Zone 20 (II 1D) |

| Dust ** | All dusts kinds |

| Dust concentration | No limit |

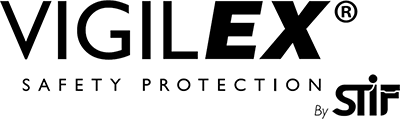

| Air flow speed | Clean air side : ≤ 30 m/s Dirty air side : ≤ 45 m/s |

| Working | Air+dust circuit Clean air circuit |

| Air flow range | Pull flow Push flow |

| Working pressure | 500mbar max |

| Working vacuum | -800mbar max |

| Elbow quantity | No limit |

*Vessel (potential explosion source)

**Organic dust, synthetic dust and metal dust